|

Applications:

- Brown stock blow tank

- Brown stock washing

- Groundwood

- TMP

- Pulpers

- HD towers

- Leveling chests

- Blend chests

- Machine chests

- Recycling pulp

- and more...

Not affected by Flow, Freeness or Temperature changes.

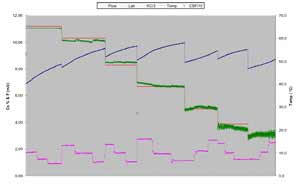

Click below to expand graph!

Excellent sensitivity, better than 0.01% Cs. |

KC/3

Blade Consistency Meter

KAJAANI PROCESS MEASUREMENTS reliable, damage resistant transmitter! Patented,

shock resistant seal-less transfer mechanism with unbreakable

diaphragm stops process from entering transmitter; all wetted

parts are constructed of titanium. Measures

a wide consistency range (2 - 16 %)! One

transmitter type fits all applications. A unique highly sensitive

eddy probe measures shear force accurately. Remote

display unit! Remote

display unit can be mounted to any desirable location. Large

display and intuitive, menu driven user interface which features

simple set-up, calibration and troubleshooting functions.

Simple calibration! One-touch

calibration sequencing makes sampling, set-up and calibration

easy. Built-in features include: time-stamping of samples

for later evaluation and calibration, calibration calculation

with multiple points and statistics, and remote selections

for different pulp grades. Low installation

and lifetime costs! Standard

stainless steel mounting saddle (titanium option available).

Seal-less transfer mechanism with no moving parts or O-rings

means low service requirements and no regular maintenance

is required. All parts are field changeable.

Features:

- Will not leak

- Two blades to cover Standard and High Consistency measurement

ranges

- Easy mechanical alignment of the blade and easy setup

- Has 7 + 1 different calibration curves with external binary

switching

- The integrated KC/3 Sampling System make possible the

collection of more realistic process information during

the sampling process

- Time stamping assures representative process data is obtained

from the line

- Will simulate an output so testing is simple – even “in

line”

- Process temperature effects are compensated by the electronics

- Output can be frozen or forced to 4 or 20ma in the event

of malfunction

- Unique memory register stores process changes for easier

troubleshooting of Cs problems

- Raw signal data shows actual shear force information from

the blade

- Shock counter identifies adverse process conditions that

may affect measurement accuracy

|